Sie brauchen leistungsstarke, aber trotzdem einfach zu betreibende Datenanalysen?

Internationale Firmen wählen uns, denn sie wollen Künstliche Intelligenz (KI) Lösungen, die

-

skalieren

Sie rollen die KI einfach in die Breite aus. -

sich selbständig anpassen

Sie haben keine Abhängigkeit von Data Scientist, da die KI sich eigenständig an Veränderungen anpasst. -

erklären

Sie können Empfehlungen / Entscheidungen der KI komplett nachvollziehen, und ihnen somit auch vertrauen.

Unsere KI-Lösungen haben sich seit Jahren 24/7 im operativen Betrieb bewährt.

Möchten Sie mehr über unsere Referenzen erfahren?

Qualität in der Produktion

Automobilzulieferer

20% schneller Fehler finden

Vorausschauende Wartung

Deutsche Bahn

90% der Kosten vermeidbar

Regenerative Energien

Energieversorger

Innovative analytische Verfahren ermöglichen zukunftsweisende Ökostrom-Lösungen

Qualität in der Produktion

Baumaterial

Aus über 5.000 Einflüssen die knapp 20 Parameter offenbart, die negative Auswirkungen auf Qualität haben

Vorausschauende Wartung

Rechenzentrum

- Tausende Geräte angebunden

- 98% Genauigkeit

- keine Falschmeldungen

Energie

Autobauer

Optimierung des Kraftwerkbetriebes und der Stromvermarktung

Künstliche Intelligenz: Ja! Aber keine Abhängigkeit von Data Scientists!

Mit Künstlicher Intelligenz (KI) können Sie viel erreichen. Aber welche Folgekosten kommen auf Sie zu, um Ihre KI-Lösung auf Prozessveränderungen anzupassen?

Eins ist klar: Data Scientists sind rar und teuer. Daher automatisiert unsere selbstlernende und erklärende KI-Standardsoftware PREDICTIVE INTELLIGENCE einige zeitraubende Arbeiten, die sonst von Data Scientists durchgeführt werden.

Dies reduziert einerseits die Implementierungskosten für Ihre KI-Lösung und andererseits die operativen Betriebskosten. Wie das geht? Mit unserer mehrfach preisgekrönten Selbstlernalgorithmik, die das Herzstück unserer Standardsoftware PREDICTIVE INTELLIGENCE darstellt.

Dadurch werden Ihre KI-Lösungen skalierbar und über Jahre nutzbar, ohne versteckte Folgekosten.

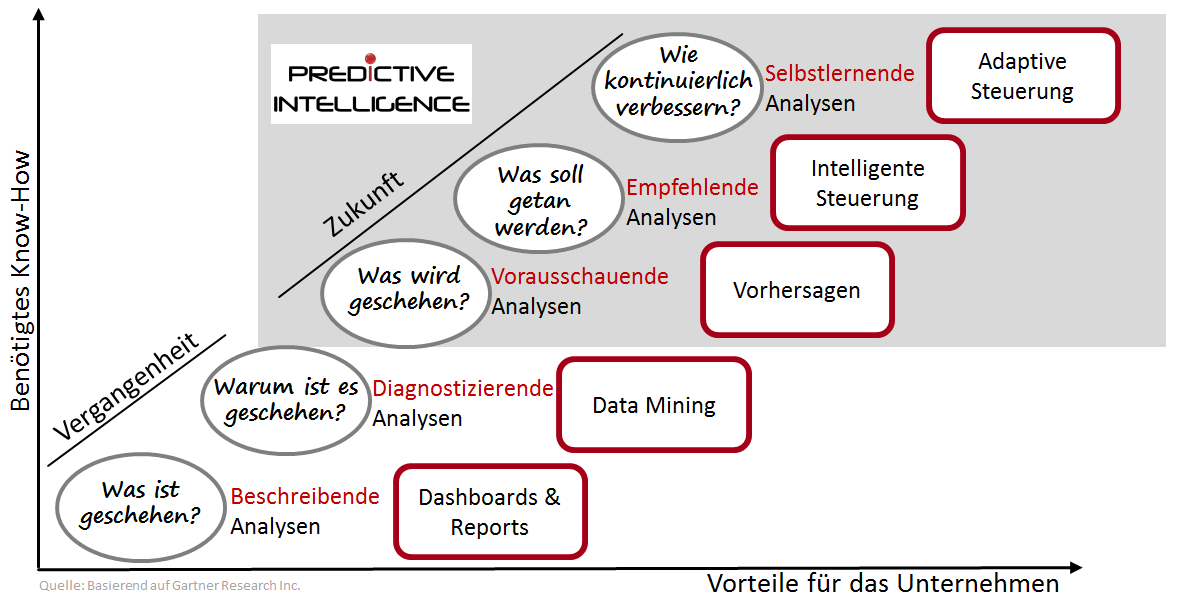

Reifegrad-Modell für IT-Analysen

Mit vorausschauenden Analysen haben

IT-Auswertungen den höchsten Reifegrad erreicht.

PREDICTIVE INTELLIGENCE

Ungeahnte Möglichkeiten mit selbstlernender, erklärender Künstlicher Intelligenz (KI) und Kognitiver Robotic Process Automation (RPA)

Einerseits sehen sich Unternehmen viel stärker als früher Kostendruck, Qualitätsansprüchen, Unplanbarkeit und steigender Prozesskomplexität ausgesetzt. Andererseits liegen in den Unternehmen immer mehr Daten über Prozesse sowie Maschinen und Ressourceneinsatz vor.

Die Verfügbarkeit dieser (Big) Data bringt jedoch noch nicht die erhoffte Effizienzsteigerung – erst Smart Data decken Ineffizienzen und Störfaktoren in fachlichen und technischen Prozessen auf.

Vorausschauende Analyse und Steuerung: Skalierbar, selbstlernend, unüberwacht und erklärend.

PREDICTIVE INTELLIGENCE ist eine unüberwacht selbstlernende und erklärende KI-Standardsoftware. Sie erhalten auch in komplexen Prozessen und dynamischen Datenstrukturen weitsichtige Empfehlungen für Ihren operativen Betrieb. Maschine-zu-Maschine-Kommunikation erlaubt direkte Prozess- und Maschinensteuerung mit nachgewiesener Effizienzsteigerung.

Dynamische Simulationsverfahren decken verborgene Optimierungspotentiale auf.

PREDICTIVE INTELLIGENCE ist eine unüberwacht selbstlernende und erklärende KI-Standardsoftware. Sie erhalten auch in komplexen Prozessen und dynamischen Datenstrukturen weitsichtige Empfehlungen für Ihren operativen Betrieb. Maschine-zu-Maschine-Kommunikation erlaubt direkte Prozess- und Maschinensteuerung mit nachgewiesener Effizienzsteigerung.

Dynamische Simulationsverfahren decken verborgene Optimierungspotentiale auf.

Störfaktoren werden frühzeitig erkannt und somit Ineffizienzen vermieden, bevor diese entstehen!

Im Gegensatz zu anderen KI-Verfahren (wie bspw. Deep Learning) erhalten Sie mit PREDICTIVE INTELLIGENCE die Transparenz darüber, welche Faktoren Ihre Prozesse positiv oder negativ beeinflussen. So können Sie Ihre Prozesse nachhaltig verbessern.

Unsere Lösungen, die vielfach mit Innovationspreisen ausgezeichnet wurden, erhöhen nachweisbar die Effizienz von Mensch, Maschine, Material sowie Energie.

- Vorausschauende Qualität (Produktion)

Qualität von Produktionsschritten bewerten und vorhersagen. Verwobene Störfaktoren und versteckte Maschinenanomalien aufdecken. Vorausschauende Steuerung von Anlagen (Maschine-zu-Maschine Steuerung oder als Empfehlung für Maschinenführer). -

Vorausschauende Wartung

Erste Anzeichen von zukünftigen Ausfällen erkennen. Verschleißgründe aufdecken. Maßnahmen für Maschinenwartung und Maschinensteuerung empfehlen. -

Vorausschauende Energie (Industrie)

Energie prognostizieren. Störfaktoren auf Energieeffizienz aufdecken. Energiehandel vorausschauend automatisieren. -

Vorausschauende Energienetze

Potential erneuerbarer Energien voll ausnutzen. Energieeinkauf und -verkauf (auch für Erneuerbare) präzise durchführen. Energiehandel vorausschauend automatisieren. -

Vorausschauende Gebäude

Gebäude vorausschauend und adaptiv steuern. -

Vorausschauender Vertrieb

Produktabsätze prognostizieren. Einflüsse auf Verkäufe aufdecken. Kundenindividuelle Werbung ermöglichen. Retouren reduzieren. Optimale Preise empfehlen. -

Streaming Analytics

Prognosen und Empfehlungen auf Echtzeitdaten ohne Zeitverlust. -

Softwaremodule

Selbstlernen, Anomalieerkennung, vorausschauende Steuerung, Vorhersage, Analyse, Simulation, Daten- und Benutzermanagement